Rytec System 3 Manual: A Comprehensive Guide

This manual details installation, operation, and maintenance of the Rytec System 3 Drive & Control, ensuring optimal performance and safety for industrial door systems․

Welcome to the Rytec System 3, a sophisticated drive and control system designed for a diverse range of industrial door applications․ This manual serves as your comprehensive resource, guiding you through the intricacies of installation, operation, and long-term maintenance․ The System 3 boasts advanced features and a robust construction, making it an ideal solution where precise control and unwavering safety are paramount․

Understanding the detailed content within this manual is absolutely critical․ It ensures not only optimal functionality of your door system but also contributes significantly to its overall longevity․ The installation process, while straightforward when following the outlined procedures, requires careful attention to detail․ Any unauthorized modifications or deviations from these instructions will unfortunately void the product warranty․

This guide is structured to provide clear, concise instructions, empowering you to maximize the benefits of your Rytec System 3 investment․ We encourage you to familiarize yourself with its contents before commencing any work․

System 3 Drive & Control Overview

The Rytec System 3 Drive & Control represents a significant advancement in industrial door automation․ It’s engineered to deliver reliable performance and precise control, catering to a wide spectrum of door types and operational demands․ This system integrates seamlessly, offering a user-friendly experience alongside robust functionality․

At its core, the System 3 utilizes advanced motor control technology, ensuring smooth acceleration, deceleration, and consistent operation․ The control panel interface provides intuitive access to programming parameters, allowing for customized settings tailored to specific application requirements․ Key features include adjustable speed and acceleration, open and close limit settings, and compatibility with various safety devices like photo eyes․

Furthermore, the System 3 is designed for easy integration with timers and scheduling functions, enhancing operational efficiency․ Its robust construction guarantees durability, even in demanding industrial environments․ Proper installation and adherence to the guidelines within this manual are crucial for maximizing system performance․

Safety Precautions and Warnings

Prior to installing or servicing the Rytec System 3, carefully review all safety precautions outlined in this manual․ Improper handling can result in serious injury or equipment damage․ Disconnect power to the system before performing any maintenance or repairs; Always verify the power is off using a reliable testing device․

Qualified personnel should perform all installation and programming procedures․ Unauthorized modifications to the system will void the warranty and may compromise safety features․ Ensure all wiring connections are secure and comply with local electrical codes․ Never bypass or disable safety devices such as photo eyes or obstruction detection systems․

Be aware of moving door components during operation and testing․ Keep clear of the door’s path and avoid placing objects in the operating area․ Regularly inspect the system for signs of wear or damage, and address any issues promptly․ Failure to heed these warnings could lead to hazardous situations․

Installation Procedures

Follow outlined procedures carefully to ensure correct System 3 installation; unauthorized changes void the warranty and may compromise system functionality and safety․

Unpacking and Inspection

Upon receiving your Rytec System 3, carefully inspect the shipping container for any signs of damage incurred during transit․ Document any external damage immediately with photographs and notify the carrier and Rytec customer support․ Once the container is opened, meticulously inventory all components against the packing list to ensure everything is present․

Verify that the System 3 Control, drive unit, encoder, and all associated hardware and accessories are included․ Check each component for visible defects, such as dents, scratches, or broken parts․ Any discrepancies or damage should be reported to Rytec immediately․ Retain all original packaging materials until the installation is complete and you are satisfied with the condition of the system․ Proper inspection prevents delays and ensures a smooth installation process, safeguarding your investment․

Mounting the System 3 Control

Select a clean, dry, and easily accessible location for mounting the System 3 Control, protecting it from dust, moisture, and extreme temperatures․ Ensure sufficient space around the control for wiring and ventilation․ The enclosure should be securely fastened to a stable surface using appropriate mounting hardware – screws and anchors suitable for the wall material are essential․

Maintain the specified clearances around the unit, as detailed in the technical specifications, to prevent overheating and ensure proper operation․ Avoid mounting near strong electromagnetic interference sources; Before securing the control, double-check that all wiring connections can reach comfortably․ Proper mounting ensures stable operation and simplifies future maintenance, contributing to the longevity of the system․

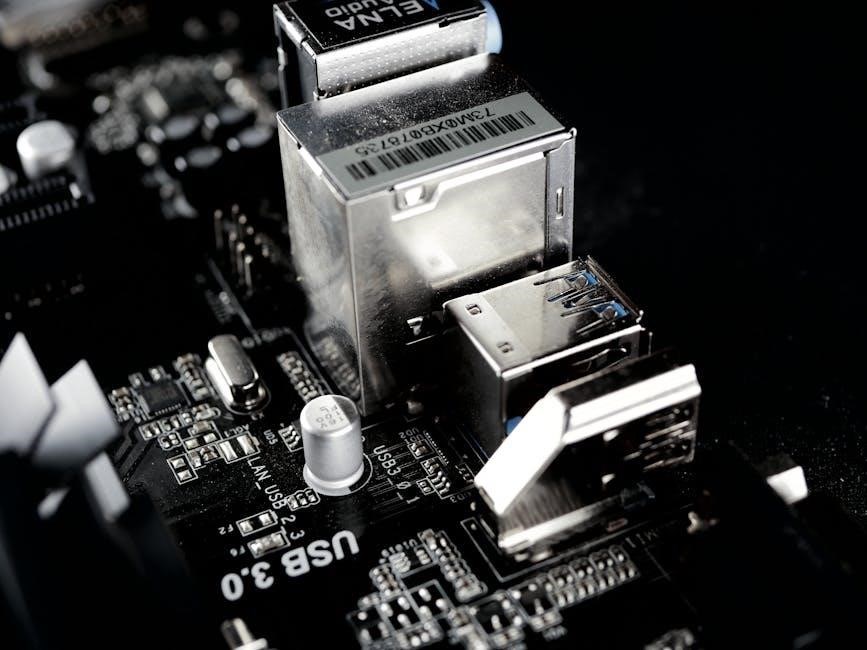

Wiring Diagram and Connections

Refer to the detailed wiring diagram included in this manual before making any connections․ Ensure the power supply matches the System 3’s electrical requirements – incorrect voltage can cause damage․ All wiring must comply with local and national electrical codes; Properly ground the control enclosure to prevent electrical shock and ensure system stability․

Connect the motor leads, encoder, and safety devices (photo eyes, safety edges) according to the diagram․ Use appropriately sized wire and secure all connections tightly․ Double-check all connections before applying power․ Incorrect wiring can lead to malfunction or damage․ A qualified electrician should perform all wiring if you are not comfortable with electrical work, guaranteeing a safe and functional installation․

Encoder Installation and Adjustment

Proper encoder installation is crucial for accurate door positioning and operation․ Mount the encoder securely to the motor, ensuring the shaft is properly aligned․ Verify the encoder disc is clean and free of obstructions․ Connect the encoder wiring to the System 3 control, referencing the wiring diagram for correct pin assignments․

After installation, encoder adjustment is necessary․ Access the encoder settings through the control panel interface․ Calibrate the encoder by moving the door through its full range of motion․ Fine-tune the encoder resolution to achieve precise control and smooth operation․ Incorrect encoder settings can result in erratic door movement or inaccurate limit settings․ Consult the programming section for detailed adjustment procedures․

Operation and Programming

The System 3 offers a user-friendly control panel interface for programming, allowing customization of parameters like open/close limits, speed, and acceleration settings․

System 3 Control Panel Interface

The Rytec System 3 control panel provides a straightforward interface for operators, featuring a clear display and intuitive button layout․ This allows for easy navigation through programming menus and real-time monitoring of system status․ Key functions, such as adjusting operational parameters and reviewing fault codes, are readily accessible․

The interface typically includes buttons for manual operation – Open, Close, and Stop – alongside programmable function keys․ A digital display presents crucial information like current position, speed settings, and any active error messages․ Understanding the panel’s indicators and utilizing the programming functions are essential for maximizing the system’s efficiency and ensuring safe operation․

Operators can easily adjust settings to suit specific application needs, enhancing control and responsiveness․ The panel’s design prioritizes user-friendliness, minimizing the learning curve and promoting efficient troubleshooting․ Regular review of the control panel display is recommended for proactive maintenance and early detection of potential issues․

Basic Programming Parameters

The Rytec System 3 allows customization through several basic programming parameters, enabling tailored operation for diverse applications․ These include adjustments for start delay, controlling the initial pause before door movement, and slow down settings, influencing deceleration near limits․ Run time parameters define the duration of open and close cycles, while re-close time governs automatic re-closure attempts after obstruction․

Understanding these parameters is crucial for optimizing performance and ensuring safety․ Incorrect settings can lead to operational inefficiencies or potential hazards․ The control panel interface provides access to these settings, allowing authorized personnel to modify them according to specific needs․

Careful consideration should be given to each parameter, referencing the manual for detailed explanations and recommended values․ Regularly reviewing and adjusting these settings, based on usage patterns and environmental factors, will contribute to the longevity and reliability of the System 3;

Setting Open and Close Limits

Precisely defining open and close limits is fundamental to safe and efficient Rytec System 3 operation․ These limits dictate the maximum travel distance of the door in both directions, preventing over-extension or collision․ Programming involves utilizing the control panel interface to input desired values, typically expressed in seconds or encoder pulses․

Accurate limit setting requires careful observation and incremental adjustments․ Begin with conservative values and gradually increase or decrease them until the door reaches the desired open and closed positions․ It’s vital to verify these settings multiple times, ensuring consistent and reliable operation․

Incorrectly set limits can compromise safety and damage the door or system․ Always double-check values and test thoroughly before full operation․ Refer to the manual for specific guidance on limit adjustment procedures and troubleshooting common issues related to limit settings․

Adjusting Speed and Acceleration

Optimizing door speed and acceleration is crucial for balancing efficiency and safety with the Rytec System 3․ The control panel allows for precise adjustments to these parameters, influencing how quickly the door opens, closes, and changes velocity․ Slower speeds enhance safety, particularly in high-traffic areas, while faster speeds improve throughput․

Acceleration settings control the rate at which the door reaches its set speed․ Gradual acceleration minimizes stress on the system and reduces the risk of jolting movements․ Conversely, quicker acceleration shortens cycle times․ Careful consideration of the door’s weight, size, and operating environment is essential․

Always test adjustments thoroughly after making changes․ Monitor the door’s performance for smooth operation and ensure it doesn’t exceed safe limits․ Refer to the manual for recommended speed and acceleration ranges for various door types and applications․

Advanced Features

The Rytec System 3 boasts features like photo eye integration, timer functions, breakaway configuration, and adjustable obstruction detection sensitivity, enhancing control and safety․

Photo Eye Integration

Integrating photo eyes with the Rytec System 3 significantly enhances safety and operational efficiency․ These sensors detect obstructions in the door’s path, preventing accidental closures and potential damage to people or property․ The System 3 supports various photo eye configurations, including through-beam and reflective types, offering flexibility for different installation environments․

Proper wiring and configuration are crucial for optimal performance․ The manual provides detailed wiring diagrams and programming instructions to ensure seamless integration․ Sensitivity adjustments allow users to fine-tune the photo eye’s responsiveness, minimizing false triggers while maintaining a high level of safety․

During setup, verify correct alignment and signal strength․ Incorrectly positioned or malfunctioning photo eyes can compromise the system’s safety features․ Regularly test the photo eye functionality as part of routine maintenance to ensure continued reliable operation․ The System 3’s control panel provides diagnostic information to assist in troubleshooting any photo eye related issues․

Timer Functions and Scheduling

The Rytec System 3 offers robust timer functions and scheduling capabilities, allowing for automated door operation based on pre-defined time intervals․ This feature is ideal for facilities requiring controlled access during specific hours or for energy conservation by minimizing door usage outside of operational times․ The system supports multiple timer settings, enabling customized schedules for different days of the week․

Programming timers is straightforward through the System 3 control panel․ Users can set start and end times, as well as specify the desired operational mode (open, close, or hold)․

Advanced scheduling options include holiday overrides and event-based triggers․ These features provide further flexibility and control over door operation․ Regularly review and update the timer schedules to ensure they align with current operational needs․ Proper configuration of timer functions can significantly improve security and efficiency․

Breakaway Function Configuration

The Rytec System 3’s breakaway function is a critical safety feature designed to protect personnel and equipment in the event of obstruction during door closure․ This function allows the door to automatically reverse direction upon encountering resistance, preventing potential damage or injury․ Proper configuration of the breakaway sensitivity is essential for optimal performance․

Adjustment is performed via the System 3 control panel, offering multiple sensitivity levels to accommodate varying door weights and environmental conditions․ Lower sensitivity settings are suitable for lighter doors or areas with frequent minor obstructions, while higher settings are recommended for heavier doors or environments prone to significant resistance․

Regular testing of the breakaway function is crucial to ensure it operates correctly․ Incorrect settings can lead to either insufficient protection or nuisance tripping․ Refer to the troubleshooting section for guidance on resolving any issues related to the breakaway function․

Obstruction Detection Sensitivity

The Rytec System 3 utilizes advanced obstruction detection to enhance safety during door operation․ This system employs sensors to identify obstacles in the door’s path, initiating an immediate reversal to prevent collisions․ Fine-tuning the sensitivity is paramount for reliable performance and minimizing false activations․

Sensitivity adjustments are accessible through the control panel interface, offering a range of settings to suit diverse applications and environments․ Higher sensitivity levels are ideal for areas with pedestrian traffic or potential for small obstructions, while lower settings reduce the risk of nuisance trips caused by wind or minor debris․

Regularly test the obstruction detection system using a soft object to verify proper functionality․ Incorrect sensitivity settings can compromise safety or disrupt normal operation․ Consult the troubleshooting guide for solutions to any detection-related issues․

Troubleshooting and Maintenance

This section provides solutions for common fault codes, emergency procedures, routine maintenance schedules, and component replacement guidelines for the Rytec System 3․

Common Fault Codes and Solutions

Understanding the System 3’s fault code system is crucial for efficient troubleshooting․ The controller displays codes indicating specific issues, allowing for targeted repairs․ For example, a “101” code often signifies an obstruction detected by the safety devices, requiring inspection of photo eyes or safety edges․ A “202” code may point to encoder issues, necessitating adjustment or replacement․

Regularly consult the full error code list within this manual for a comprehensive understanding of each code’s meaning and potential causes․ Solutions range from simple adjustments – like re-setting limits – to more complex repairs involving wiring checks or component replacement․ Always disconnect power before performing any maintenance․ Ignoring fault codes can lead to system malfunction and potential safety hazards․ Prioritize addressing codes promptly to maintain optimal door operation and prevent further damage․ Detailed diagrams and step-by-step instructions are provided for common fixes;

Emergency Operation Procedures

In the event of a power outage or system malfunction, understanding emergency operation is paramount for safety․ The Rytec System 3 is equipped with a manual release mechanism, allowing for manual door operation․ Locate the release lever (refer to the mounting section for its specific location) and disengage the chain․

Exercise extreme caution when manually operating the door, ensuring no personnel are in the path of movement․ The door will not have safety features active in manual mode․ After restoring power, re-engage the chain to resume automatic operation․ If the system repeatedly fails, do not attempt continued manual operation; contact a qualified technician․ Regularly test the manual release to ensure it functions correctly․ Familiarize all personnel with these procedures to ensure a swift and safe response during emergencies․

Routine Maintenance Schedule

To ensure optimal performance and longevity of your Rytec System 3, adhere to this maintenance schedule․ Monthly: Inspect the drive chain for proper tension and lubrication; adjust or lubricate as needed․ Check all wiring connections for tightness and damage, addressing any issues immediately․ Quarterly: Examine the encoder for debris and ensure proper alignment․ Verify the functionality of all safety devices, including photo eyes and obstruction detection․

Annually: Conduct a thorough inspection of the entire system, including the control panel, motor, and gearbox․ Replace worn components as necessary․ Professional servicing is recommended annually to ensure comprehensive system health․ Keep a detailed log of all maintenance performed․ Following this schedule minimizes downtime and extends the life of your Rytec System 3;

Component Replacement Guidelines

When replacing components on your Rytec System 3, always prioritize using genuine Rytec replacement parts to maintain system integrity and warranty validity․ For the control panel, disconnect power before any work begins and carefully label all wiring․ Motor replacement requires verifying voltage and horsepower compatibility․ Encoder replacement demands precise alignment for accurate operation; consult the installation section for detailed instructions․

Drive chain and sprocket replacement should be done as a set to ensure proper meshing․ Safety device replacement necessitates thorough testing after installation․ Always refer to the technical specifications for correct part numbers․ Improper component replacement can lead to system malfunction or safety hazards․ If unsure, contact a qualified Rytec technician․

Technical Specifications

The Rytec System 3 operates on specified electrical requirements and within defined environmental conditions, ensuring compatibility with various door types and a valid warranty․

System 3 Electrical Requirements

The Rytec System 3 Drive & Control demands careful attention to electrical specifications for safe and reliable operation․ Typically, the system requires a dedicated electrical circuit, adhering to local and national electrical codes․ Input voltage requirements generally fall within a range of 110-240VAC, 50/60Hz, though specific models may vary; always consult the unit’s nameplate for precise details․

Proper grounding is absolutely critical to prevent electrical shock and ensure correct system functionality․ The control panel must be securely grounded to a verified earth ground․ Furthermore, appropriate circuit protection, such as fuses or circuit breakers, must be installed to safeguard against overcurrents and short circuits․ It’s essential to verify that the electrical supply can handle the system’s inrush current, which can be significantly higher than the running current․ Failure to meet these electrical requirements will void the warranty and potentially create a hazardous situation․

Environmental Operating Conditions

Maintaining optimal environmental conditions is crucial for the longevity and performance of the Rytec System 3 Drive & Control․ The system is generally designed to operate effectively within a temperature range of -20°C to +50°C (-4°F to 122°F), however, extreme temperatures can impact performance․

Humidity levels should be maintained between 20% and 95% non-condensing to prevent corrosion and electrical issues․ Avoid direct exposure to rain, snow, or excessive moisture․ The System 3 is suitable for indoor use, but if outdoor applications are necessary, ensure the control panel is housed in a properly sealed and ventilated enclosure․ Dust and debris can also affect operation; regular cleaning is recommended, especially in harsh industrial environments․ Exposure to corrosive substances should be avoided․ Operating outside these specified conditions may void the warranty․

Door Type Compatibility

The Rytec System 3 Drive & Control demonstrates versatile compatibility, effectively managing a wide spectrum of door types commonly utilized in industrial and commercial settings․ This includes, but isn’t limited to, sectional doors, rolling steel doors, high-speed doors, and coiling doors․ However, specific door weight and size limitations must be observed to ensure safe and reliable operation․

The system is engineered to accommodate doors with varying spring configurations, including torsion and counterbalance systems․ Proper door balance is paramount before installation; an unbalanced door can cause excessive strain on the operator and potentially lead to failure․ Compatibility also extends to different door materials, such as steel, aluminum, and wood․ Always verify the door’s weight and dimensions against the System 3’s specifications to guarantee optimal performance and prevent damage․ Consult the full manual for detailed compatibility charts and guidelines․

Warranty Information

Rytec provides a comprehensive warranty on the System 3 Drive & Control, safeguarding against defects in materials and workmanship․ The standard warranty period is typically one year from the date of installation, though extended warranty options may be available․ This warranty covers component replacement or repair at Rytec’s discretion, but does not cover damage resulting from improper installation, misuse, or unauthorized modifications․

Crucially, adherence to the installation and operating procedures outlined in this manual is essential to maintain warranty validity․ Any alterations to the system or failure to follow recommended maintenance schedules will void the warranty․ Claims must be submitted with proof of purchase and a detailed description of the issue․ Rytec reserves the right to inspect the faulty component before authorizing repair or replacement․ For complete warranty details and claim procedures, please refer to the separate warranty document provided with your System 3․